About system WireLocks

DIGITAL PLANNING

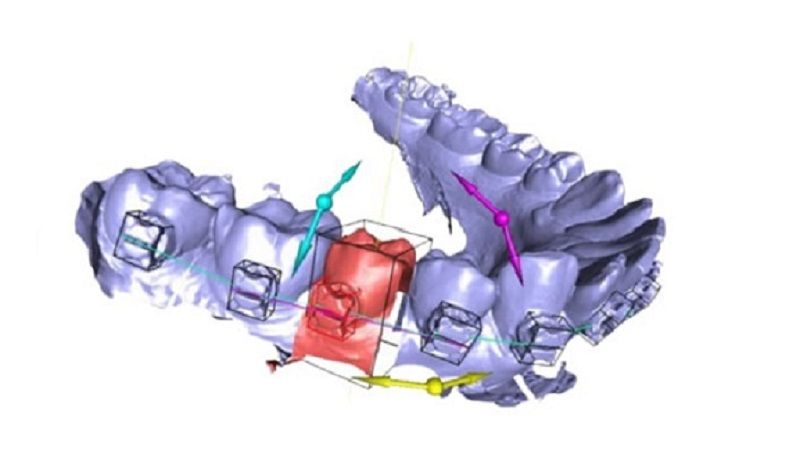

WireLocks digital orthodontic technology plans each stage of bite correction and ensures the exact implementation of this plan due to the machine production (bending) of orthodontic wire, which precisely affects each element of the system, taking into account the biomechanics of tooth movement.

The high speed of orthodontic treatment is achieved by a constant, precisely dosed directed pressure of a wire spring, individually curved for each stage of treatment.

The use of a specially designed computer application allows you to plan not only bite setups, but also the shape of the orthodontic wire for each setup, which in turn creates controlled forces and thereby reduces excessive load on the horizontal bracket slot and its wear.

For accurate planning of the position of the tooth you need to understand the exact position of the bracket, for this we use the features of the bracket model and transfer thanks to the capabilities of the computer program

BRACKET VERTICAL AND HORIZONTAL SLOT

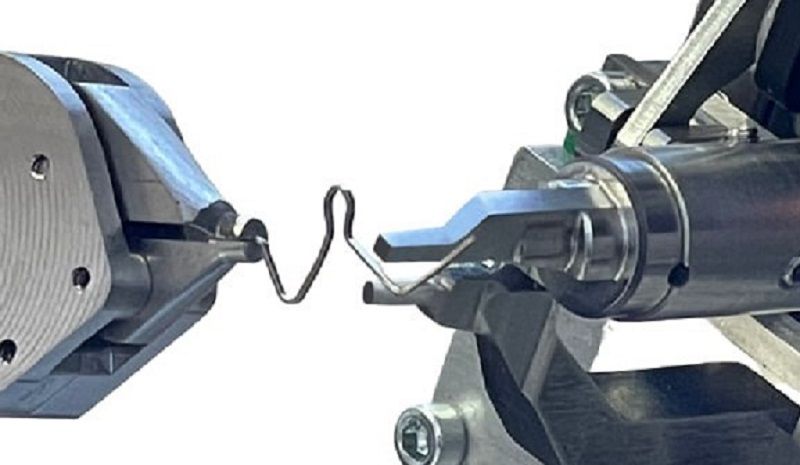

Rigid fixation of the wire spring is provided by a special form of a vertical slot in the bracket, in which the orthodontic wire curved in the form of a loop “snaps” according to the principle of push-button fixation.

At the same time, the uniqueness of the WireLocks system lies in the absence of play between the wire and the bracket, which creates exceptional conditions for complete control over any planned movement of a tooth or group of teeth. The dentition will inevitably take the position planned in the computer program, and not only the tooth itself, but also its root will be in the desired position.

Such predictability allows solving any clinical problems without additional devices (springs, buttons, cantilevers, orthodontic screws, etc.).

The use of a horizontal slots in our braces allows us to use the well-known sliding principle. At the same time, the material used by us contributes to good sliding and precise control of torque and angulation.

The presence of both vertical and horizontal slots in the bracket makes it possible to use all the scientific experience gained in orthodontic treatment, and a transparent high-strength organic glass bracket provides high aesthetics and full adhesion to the fixing material.

The shape of the bracket has an important difference from all existing models, the shape of the wings used for alloying the wire allows you to accurately transfer data on the position of the bracket on the tooth, as well as to make a positioner already on the bracket installed on the tooth.

Replacing the wire spring occurs within 3-5 minutes and does not require the use of special tools.

Thus, the WireLocks orthodontic system allows you to receive a significantly larger number of patients with a fully predictable quality of orthodontic treatment.

Robotic production

Modern digital reality gives us opportunities that were previously unattainable thanks to the combination of science and robotics.

The machine we have created, which produces the orthodontic wire structure specified in the computer program, has unique capabilities that have never existed before: simultaneously with the bending of the orthodontic wire in the shape of the vertical slot of the bracket, it also forms the spring of the planned shape in accordance with each stage of treatment. At the same time, the machine allows you to make almost any bends with minimal restrictions.

This high-tech tool allows the orthodontist to solve any clinical problems in the shortest possible time with minimal labor costs.

© 2022 All rights reserved.